Why a Year-End Checklist Pays for Itself

Unplanned downtime is expensive. In 2024, the average cost of downtime across industries hovered around $25,000 per hour for many organizations; larger operations may see higher losses. The heavy equipment industry has seen costs increase significantly since 2019, making a focus on prevention an important part of every operation.

Bobcat Company's guidance emphasizes staying on schedule — filters, fluids, and inspections at specific hour intervals—to keep machines at peak performance. Pair that with Machine IQ telematics for maintenance alerts and remote engine disable/enable, and you help reduce risk while protecting your assets.

The Quick-Scan Year-End List (print this)

Use this list across your Bobcat skid-steer loaders, compact track loaders, compact excavators, Toolcat utility work machines, and zero-turn mowers. Always remember to follow the maintenance schedule in your model’s Operation & Maintenance Manual and service decals.

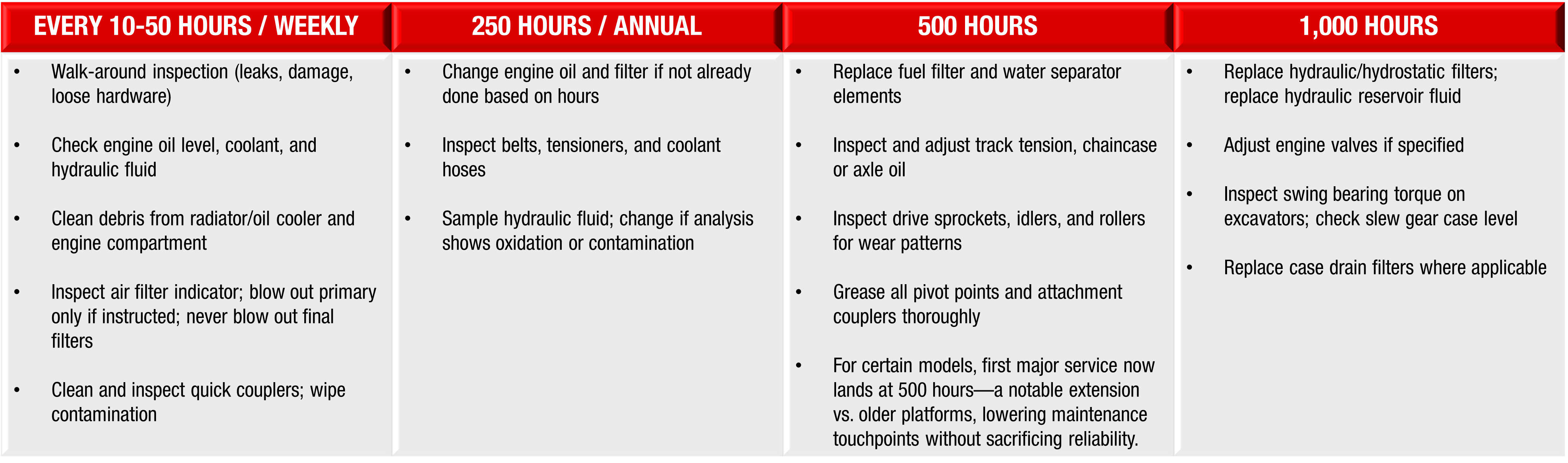

Hour-Based Tasks to Wrap Up the Year

Bobcat service schedules maintenance tasks by operating hours. Below is a model-agnostic guide for planning your service, however your machines’ operations and maintenance manual will include a list specific to your unit. Best practice is to use your model specific maintenance list. Always follow the model-specific schedule.

Winterization Specifics for Texas Fleets

Texas sees dramatic temperature swings, dust, and occasional hard freezes. Prepping now prevents surprises in the new year.

Fluids and cold starts

- Confirm winter-grade engine oil where ambient lows demand it; verify cold-start aids function.

- Test batteries at 32°F equivalent; borderline batteries fail when the first cold snap hits.

- For diesel: manage fuel quality and consider anti-gel additives if forecast lows justify it. (Use OEM-approved products.)

DEF management

- Keep DEF between 15°F and 77°F and out of direct sunlight. Use API-certified DEF only. Label funnels and containers strictly for DEF to prevent contamination.

Cooling and HVAC

- Confirm freeze point; pressure-test caps; ensure cab heat/defrost and wipers work for safety.

Undercarriage and Tires

- Set correct track tension and tire pressure at cool temperatures for accurate readings. Inspect for cuts from hot, dry summer conditions.

Use Telematics to Make This Easy

Machine IQ centralizes maintenance tracking: operating hours, fuel use, location history, alerts, and remote engine disable/enable for theft deterrence and recovery. Assign due-soon services by hours and push notifications to your shop calendar.

Pro tip: At year-end, export hours and service history, reconcile with parts invoices, and set a preventive task schedule. If you’re not set up with MachineIQ, our team can help you enroll your fleet. Contact us at 214-971-7467 or fill out a Contact form on our Telematics page.

Parts, Service, Rentals: When to Tap the BobcatCCE Team

● Parts: Genuine Bobcat filters, fluids, and parts protect performance. With one of the largest Bobcat parts inventories in Texas and multiple ways to buy, you keep projects moving. Get parts now.

● Service: Factory-trained technicians handle everything from annual services to major repairs, across 18 locations statewide. Schedule your year-end service now.

● Rentals: Park a machine for maintenance or repair and rent a unit to cover peak demand. Day, week, or long-term options available. Get pricing for a rental in your area.

● Promotions/Catalogs: Check current offers and download the latest catalogs to plan upgrades and attachment buys.

● Telematics: If you want automated maintenance reminders and security features, submit a Telematics inquiry.

● Attachments: From augers to grapples, find the right tool for every task. Explore our full lineup of Bobcat attachments to boost versatility and productivity on any job. See attachment options.

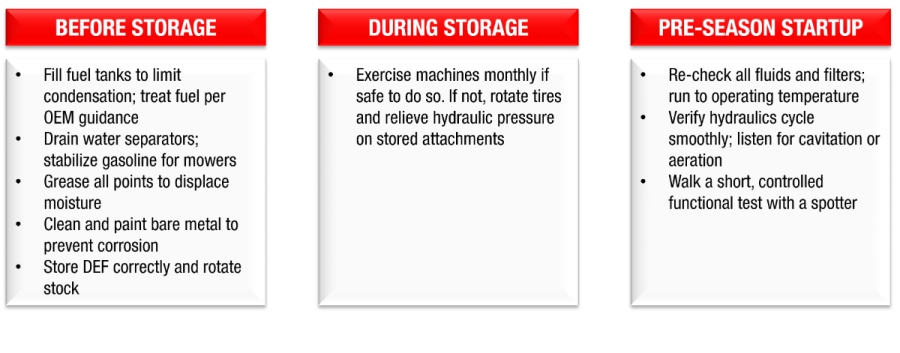

Storage and Startup Checklist

Before you park your equipment or fire it back up, take a minute to run through this storage and startup checklist. A little prep goes a long way in keep your Bobcat equipment ready for the next job.

What This Saves You

Preventive maintenance can help reduce unexpected breakdowns by up to 70%, help extend equipment life and save money by avoiding costly repairs and downtime. Year-end service pays for itself in reduced rental costs, lost billable hours, and rush charges on needed parts.

Prep Today. Perform Tomorrow.

A little year-end maintenance goes a long way toward smoother starts and fewer surprises. Contact your local BobcatCCE service team to book you year-end inspection and get your fleet ready for whatever comes next.